Milk production is affected by many links, specifically manifested in: cow comfort, udder hygiene and health, cow house/milking hall/milking equipment hygiene, milking procedures, milk filtration and milk cooling, milking/refrigeration equipment cleaning and other links. Milk filtration maximizes milk quality and value while also protecting milking and refrigeration equipment from potentially harmful foreign bodies. This means that filtration benefits the rancher in two ways: by maximizing the life of the milking equipment, it reduces the cost of the equipment.

Filtration is the process of separating species from other substances. Depending on the industry and the substance to be separated, a variety of filtration systems can be used, including electrostatic precipitators, centrifugal filters, cyclone separators, scrubbers and mechanical separators. To ensure that the milk’s nutritional content is not destroyed, farms often use mechanical filters to filter the milk, separating the solid particles suspended in the milk from the udder tissue before it enters the cold tank. The substances that are filtered are feces, straw, hair, clots and insects, all of which can darken milking equipment and contaminate the milk in the cold tank. But pasture milk filtration is not a solution to poor, unsanitary milking procedures, but a good and overall milking management plays an important role in the best measure.

Examination of the milk filter paper at the end of milking is a good indication of the health of the herd’s udders and can indicate the adequacy of the teat preparation prior to milking. The presence of mucus or clots on the milk filter paper indicates that a cow in the herd has clinical mastitis.

Mechanical filtration of pasture milk

Mechanical filtration is a process used in the filtration of milk in pasture, characterized by pore size between 100 and 250 µm and working pressure of about 50kPa. Fat globules and other nutrients in milk can pass through milk filter paper, while feces, insects or other particulate matter can be trapped.

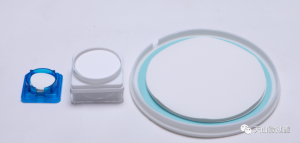

The mechanical filtration method used to filter thousands of milks in pastures is also known as barrier filtration. This is because the filter paper provides a porous physical barrier with highly specialized properties that separate the solids from the milk. The driving force of the filtration process comes from the pressure difference between the two sides of the milk filter paper. When the pumped milk flows over the porous surface of the milk filter paper, a pressure difference is created on each side of the filter paper. This pressure difference enables components (e.g. water, fat, protein, etc.) smaller than the pore size of the milk filter paper to pass through the filter paper. And Daqian milk filter paper aperture of any composition (including straw, hair, insects, etc.) can not pass through the filter paper, is trapped in the milk filter paper. The use of a pump to pass the milk through the milk filter paper is the most commonly used method in milking equipment. The milk filter paper can be mounted on a perforated metal bracket in the shape of a tube or bag, or in the shape of a cage inside a column. The best filtration performance can be obtained when the milk flows through the milk filter paper under continuous low pressure. The filter aperture becomes larger, leading to the passage of other impurities other than milk, and repeated use will lead to the degradation of the food-grade performance of the gauze. This traditional gauze filtration method will lead to a large number of impurities remaining inside the equipment, resulting in the decline of equipment performance; And the increase of impurity degree will also lead to the increase of bacteria in milk and the decrease of milk value. This violates the basic purpose of milk filtration.

Modern pasture milk production puts forward higher requirements for milk filtration. High-quality milk filter paper must have certain physical characteristics, and the selected filter paper must have the correct size and capacity to match the needs of milking equipment and herd size. The filter paper must also be made of highly uniform fabric, with the following characteristics: high wet strength, uniform pore size and distribution, strong joints, dimensional stability, reaching food grade.

The application of wet-mesh technology in nonwovens production process caters well to the above characteristics of filter paper. In the production technology of wet-mesh filter fabric, the fiber is first dispersed into water to form a uniform raw material. The mixture is then pumped to a mesh conveyor belt or a porous drum, where the fibers are randomly arranged, and then the water is drained, and finally the nonwoven fabric is dried. It is now possible with modern technology to produce webs of up to three layers of fiber, each with a unique composition. Wet-mesh material is A highly homogeneous fabric with controllable porosity and excellent filtration PROPERTIES, high wet strength and DIMENSIONAL stability.

Selection and correct selection of filter paper

In modern milking equipment, a pump is usually used to drive the milk through the milk filter paper, so the correct size of the milk filter paper for the milk flow and filter housing must be determined.

If the milk filter paper used is too small, the surface area is insufficient to achieve a better efficient filtration. During a milking shift, the flow rate will gradually decrease because cake will accumulate on the filter paper. This MAY CAUSE MILK TO FLOW FROM THE BYPASS through the filter paper, OR IN RARE CASES THE FILTER PAPER MAY BREAK AND CAUSE CAKE TO enter the filtered MILK. This can cause unfiltered milk to contaminate the cold tank or damage the plate cooler. If the volume and flow of the milk filter paper do not match the milk pump volume, the milk filter paper will not be able to withstand the pressure generated by the milk flow, so as to rupture. On the other hand, if the fruit filter paper is too large, the rancher will pay for filtration capacity and filtration characteristics that are not fully utilized and therefore not cost effective. Special milk filter papers are made from different types of highly specialized fabrics and are available in a variety of sizes. The right filter paper must be selected to complete different filtration tasks in the most suitable way. At present, various sizes of special milk filter paper can meet different needs.

In order to get the best performance of pasture milk filtration, it is very important to determine the location of milk filter paper. Milk should be filtered before reaching the refrigeration system. Warm milk in the temperature range of 36 to 38″C(98 to 100° F), milk fat is easily filtered through milk filter paper for efficient filtration. However, some problems may occur when the milk cools, for example: 0 ~ 5″C(32~40° F), the milk fat in the cold milk can not easily pass through the filter paper, may block the primary milk filter paper. This will cause the flow of milk through the filter to plunge to substandard levels.

To produce milk of the highest quality and value, and to meet the stringent requirements of public institutions and consumers, the milk filter paper must be changed at the right time and at the right frequency. In general, disposable milk filter paper should only be used for one milking shift and should be used for a certain period of time. The replacement of filter paper mainly depends on the milking equipment, herd size and the cleanliness of the cow (especially the teats). The life of the filter paper is about 8h, but it should be changed at the end of each milking shift (regardless of the length of time). As long as these regulations are followed, milk filter paper can reach its maximum potential, enabling ranchers to produce milk with the highest quality and maximum value.

If the milk filter paper is not changed at the end of each milking shift, the quality of milk production may be affected, and continued use will reduce the filtration effect of the milk filter paper. The sediment trapped by the milk filter paper continues to be washed by the flowing milk, which may wash away the bacteria attached to the particles, resulting in an increase in the number of bacteria in the cold tank of milk. The performance of milk filter paper deteriorates over time because its surface and/or pores can be blocked by trapped particles. Therefore, milk flow will decrease after one milking shift and will not be able to maintain the filtration efficiency at the beginning of the milking shift. Cleaning operation can not prolong the life of milk filter paper, nor can it improve the performance of milk filter paper. While this may help to reduce particulate deposits trapped on the surface of the milk filter paper, it does not remove deposits in the porous structure of the filter fabric. Therefore, the practice of trying to reuse the milk by washing the original milk filter paper will result in the degradation of milk quality.

Post time: Aug-22-2022